Camera Thermal Detection and Building Inspection in Montreal

Inspection with a thermal camera is an addition to visual inspection. The thermal camera is a sophisticated device that can capture information which the human eye cannot detect, i.e. heat radiation transmitted or reflected by an item. To properly interpret the information in a thermal camera it is recommended to have received some training in order to learn about the physical phenomena that produce a thermal image: calibration, types of material and their properties, reflection, environmental conditions with the wind and the ambient temperature, etc... as well as ASTM and ASNT inspection standards in buildings.

This tool has applications in several areas: industrial equipment inspection to detect moving parts or parts in electricity that overheat, building inspection to capture the loss of heat, leaks or moisture in the walls of a building, and even medical to see the heat areas of the body. In façades and parking spaces inspection Bill 122 does not require building owners to call in an expert in thermography to detect anomalies or improve the performance of the thermal insulation of the building. However, we believe that it is worthwhile for our customers to take the opportunity to not only meet the minimum security requirements of Bill 122, but also to go further by preventing future deterioration and by making the building more efficient. This, first by checking visually if the building has a significant loss of heat, leaks or intrusion of water or signs of moisture and mould in the building envelope. In professional jargon we speak of the thermal imprint or heat signature of the building. Second, once these anomalies detected, it is important to propose improvement plans for the building’s envelope by one of our specialist engineers or building architects.

BASIC CONCEPTS IN THERMOGRAPHY FOR USING A THERMAL CAMERA BY AN EXPERT ENGINEER IN BUILDING

Using a thermal imaging camera is one thing but to adjust it and interpret the results of the images is quite another. It is not enough either to be a building expert to use a thermal camera. It is essential to be trained and to know certain physical concepts and material properties. Some materials, such as metals, may exhibit a thermal signature in red pretending they are hot, while it is only the reflection of the sun or other elements in the vicinity. In other places, on a façade, it is possible that one does not detect heat leakage due to the wind.

Here are some basic principles that must be known before using a thermal camera :

- Heat transfer modes by radiation, conduction and convection. To better understand, the convection effect is found in warm air that rises like hot air that lifts up a balloon, the radiation effect with a forest fire or coal and conduction through the insulation of walls, ceilings and clothes. One must be able to recognize them on the thermal image ;

- The electromagnetic spectrum of radiation perceived: the wave length which is perceived by the thermal camera, i.e. 8-15 Um;

- The type of radiation: Emission (the surface emits radiation) Reflection (the surface reflects radiation coming from another place, not from itself) or Transmission (when a surface is pierced by radiation which is perceived and not coming from itself). Metal emits very low radiation. What we see is the reflection. Cardboard, wood, plastic and rubber have higher emissivity. This is why we put pieces of electrical insulation tape on metal surfaces to better see the radiation produced by the surface ;

- Knowing the heat regime, i.e. transitory or permanent.

Several other elements must be known, such as the use of the manual mode of the thermal camera to adjust the thermal ranges of fields of view and to optimize the captured images.

CONDITIONS AND INSTRUMENTS FOR AN IDEAL THERMAL INSPECTION

For measurements outdoors, for building envelopes, using thermal imaging cameras in summer, in full daylight, is not ideal. It is preferable to conduct thermal inspections during the fall, winter or spring. Ultimately, for the inspection of roofs, in summer during the evening, after sunset, so that it does not end up altering the thermal image by the effects of radiation from the sun or reflections.

Instruments in addition to the thermal camera such as the anemometer, the hydrometer, the smoke pencil, the humidity sensor, the contact thermometer and the endoscope, are very useful to do an analysis and interpretation of the image obtained by the thermal signature.

THE ADJUSTMENT AND INTERPRETATION OF A THERMAL IMAGE BY AN EXPERT BUILDING ENGINEER WITH SNELL CERTIFICATION IN MONTREAL

Most experts in thermography prefer manual mode image adjustment rather than automatic mode, because it often allows to optimize the contrasts of heat and make more clear and obvious certain building anomalies. The TI400 Fluke camera allows a single focus reading by distance instead of by radiation. Which allows to focus at any time compared to other instruments that focus on the differential radiation perceived. It is impossible with these instruments to focus in the presence of a surface having a uniform radiation and therefore no differential.

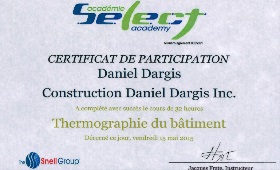

THE STANDARDS, CERTIFICATIONS AND QUALIFICATIONS, IN MATTERS OF BUILDING THERMOGRAPHY

Member engineers and architects, being building and thermal inspection experts at inspectionfacades.com, are trained and qualified with experience to conduct 100% inspections of buildings; as much from the structural and architectural point of view as from the one of the building envelope and its thermal behaviour. Formal and specific standards have been created for building thermography, such as:

- ASTM C-1060: Standard Practice for Thermographic Inspection of Insulation Installations in Envelope Cavities of Frame Buildings. A comprehensive standard that details the conditions and steps necessary to complete a thermal inspection of a building ;

- L’ASTM C-1153 : Standard Practice for the Location of Wet Insultation in Roofing Systems Using Infrared Imaging ;

- Most activities related to thermography gravitate around the E-6, C-16 and F-20 of the ASTM committees ;

- ISO 6781: Qualitative detection of thermal irregularities in building envelopes. This standard specifies the conditions and steps to conduct the inspection ;

- ISO 9721: Non-destructive testing - Qualification and certification of personnel. Similar to the ASNT-TC-1A standard. Defines how to certify and qualify the inspection staff. The difference with ASNT-TC-1A is that ISO 9712 recommends a centralized certification rather than a certification by the employer.

When we talk about certification, we talk about a diploma obtained following formal training. While the term qualification refers to the practical experience on the ground. To become an expert in thermal inspection of buildings, one does not go without the other.

A comprehensive and professional report of a thermal building inspection follows the official standards for thermal inspection. These experts have the certifications and experience in the use of the thermal camera.

THERMOGRAPHY FOR BUILDINGS

The thermal camera is used in the building field for many things, such as: checking the permeability of the roofings, the insulation and wet areas in the floors, walls, ceilings, attics and roof space and around windows, basements and other places. Thermography can sometimes have a clue about the internal behaviour of building walls and building envelopes and thus avoid searches by destructive means. Once the target area is discovered, it is just a matter of repairing locally.

It is recommended to have a temperature difference of at least 5-10°C between the inside and the outside for air infiltration inspections. The greater the temperature difference between the inside and the outside the easier will be the detection. That is why it is not recommended to conduct inspections in the summer when the temperature inside and outside of the house is the same.

It is wrong to claim that one detects mould with the thermal camera. However, the thermal camera can detect cold spots where condensation may occur and be conducive to mould. It is therefore advisable to use a different moisture detection device to detect these target points with the thermal camera.

THERMAL ROOFINGS INSPECTION

For roofings, the thermal imaging camera is used to detect anomalies on mainly flat roofs. Infrared allows therefore to locate the moisture trapped in the insulator, to do a 100% scan of the roof surface without the destructive means of a roof drilling. One should pay attention to the reflections on the membranes. Although even if the membrane is black with another emissivity, it may be bright and alter the image measurement by reflecting the radiation around on its surface. Therefore, in this case, what is perceived is the environment and not the membrane.

The thermal camera is often used to detect freezing problems, humidity, ventilation, insulation and condensation in roof attics. These phenomena are more common in the spring, when, following the cold and wet winter, in an attic or roof space poorly insulated or ventilated condensation formed ice on the walls and it melts into water which infiltrates into the ceiling of the house.

Ideal conditions and things to know for inspection of a roof :

- The roof must be dry on the day of the inspection ;

- Sunny day and light winds ;

- Clear night with no wind ;

- Knowing the type of insulation ;

- The wet insulation will be warmer during the window for inspection in the evening ;

- The temperature difference on the inside and outside is higher than 10°C.

The roof inspection standard ASTM 1153 Standard Practice for Location of Wet Insulation in Roofing Systems Using Infrared Imaging, guides us on the procedure to be used for the inspection of the roofings and the accounts report. The Canadian National Director estimate DDN 022716 includes the ASTM 1153 standard, with more stringent requirements for IR cameras, reports and qualification of the operators.

Inspectionfacades.com includes a group of façades and parking spaces building inspection experts with the expertdubatiment.com group of engineers from Montreal. This group of engineers and architects conducts the inspections of façades and parking spaces and also develops maintenance plans to improve the lifespan of buildings and their thermal performance and energy efficiency.

Do not hesitate to contact us!